At Midland Technologies, we offer several solutions for cooling hot points during the die casting process. Midland Technologies offers several options including jet coolers, bubblers, and conformal cooled inserts. We work with our customers on both standard and custom options to help with their specific applications.

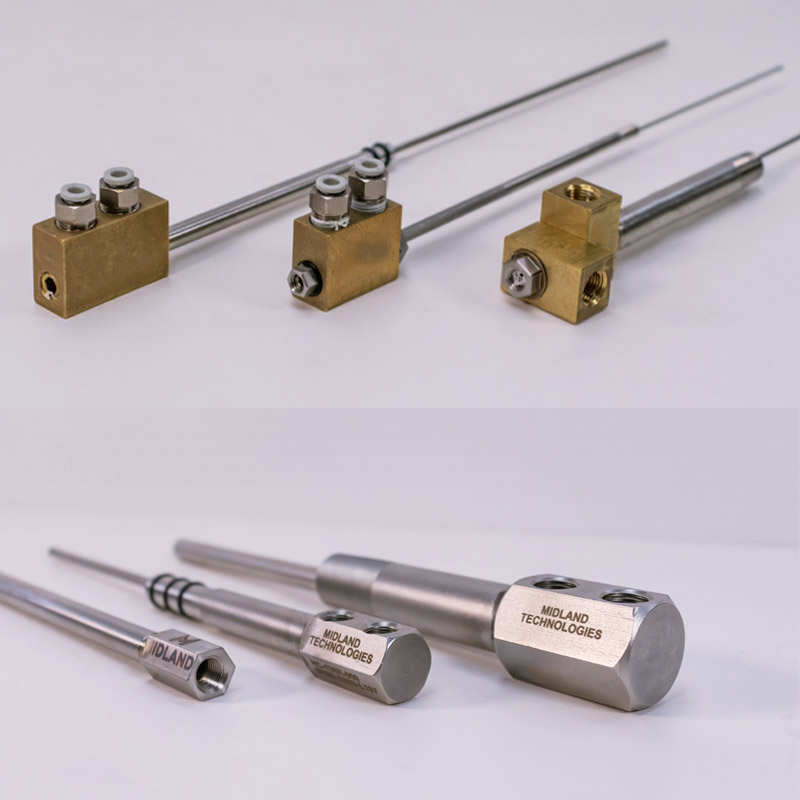

Midland Technologies high pressure jet coolers are durable, high-quality, domestically manufactured for use with high velocity jet cooling units. High pressure jet coolers consist of a rotating or stationary brass head which houses the ports for the water/air supply lines. Stainless steel tubing is used for both the outer and inner tubes at various sizes for your application. Connection to the core pin with the outer tube can be made with threads, o-rings, or a grommet. All major sub-components of the Jet Coolers have been designed in-house to support long-life and easy installation. Midland Technologies offers a typical two week turn around for standard jet cooler orders.

Midland Technologies bubblers are typically made of stainless steal and come with a rotating or stationary head. The bubblers are commonly used for components with larger cooling pins. For outer tube diameters, we offer sizes between 10mm and 21mm, and inner tube diameters between 4mm and 10mm. Bubblers without inner tubes are also available. We have also worked with our customers to create a large variety of custom sizes.

Conformal cooling solutions from Midland Technologies provide a faster and more uniform heat transfer compared to traditional cooling lines. Our conformal cooling inserts are made from premium H13 tool steel as two separate pieces, and vacuum brazed together for a high-quality component. The cooling line conforms to the outline of the part below the surface and can be designed to remove heat around specific areas. It also provides a greater volume and flow of coolant within the part.